Product name : CHINA FACTORY TYPE HLB,HLBK,HLKS,HLKT, VERTICAL MIXED FLOW PUMPS,HLBK,LKXA,B,LBXA,LBS VERTICAL OBLIQUE FLOW PUMP

Product No. : 202247161645

Details:

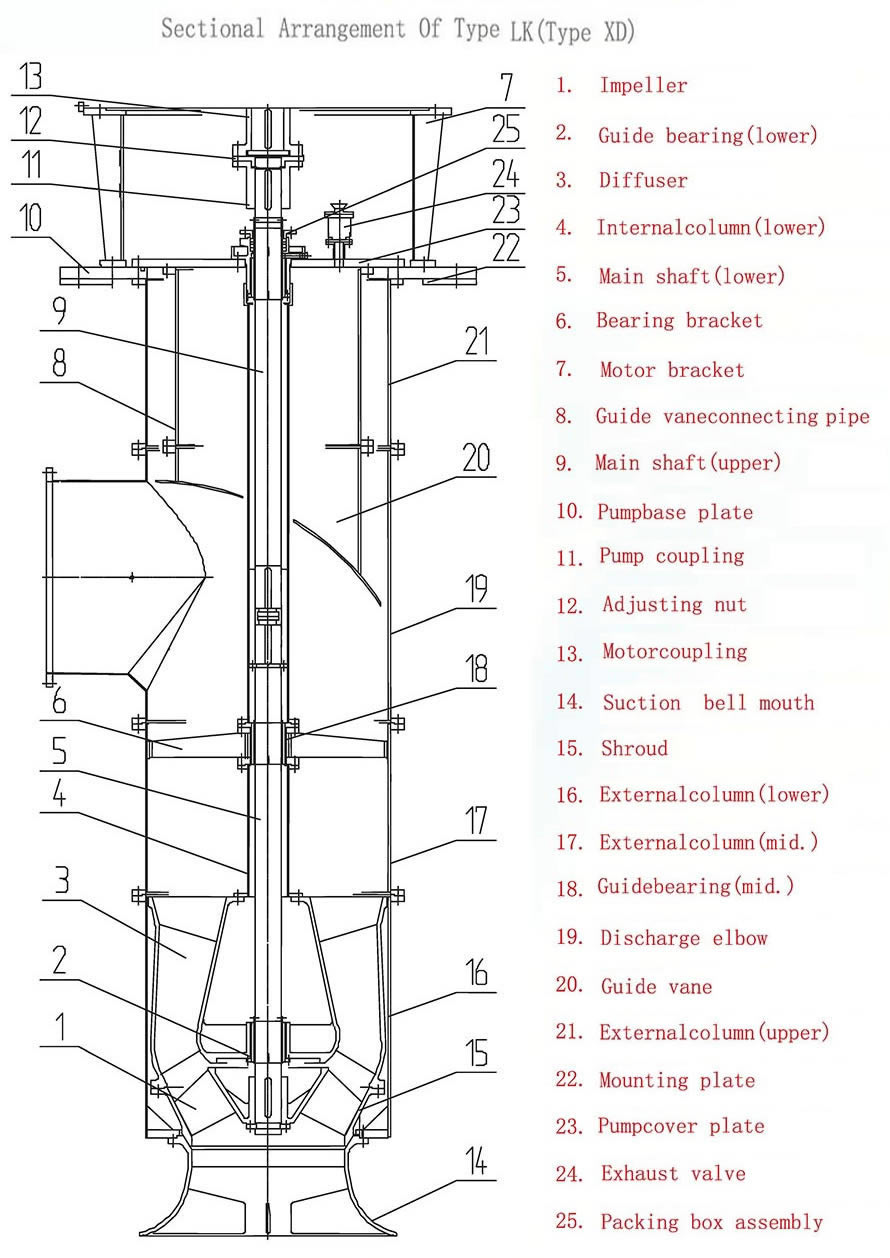

HLBK Vertical Long Shaft Axial Flow Pump(Rotor extractable type)

Description

The said series pumps are used to transfer clear water,rain water,water in iron sheet pits,sewage and seawater,servicing in power plants,iron and steel works,water supply companies,sewage treatment plants,petroleum and chemical industries,mines as well as municipal water supply and drainage projects,farmlands irriagation,flood protection and drain waterlogged farmlands,etc..The temperature of pumped media is below 550C and reaches to 900C for special design. The flow rate ranges from 30 to 20000m3/h and the head—from 7 to 200m.

Features

1. Operation smooth,safe and reliable,starting without exhausting vacumn,service life long.

2. Flowing channel simple and reliable,saving the investment for construction of the pump house.

3. Easy to be installed and dismantled. Easy to be maintained and inspected.

4. High efficiency and help saving the cost.

Model description

500HLBK2000-23

500—Outlet of the pump:500mm

HLBK----Vertical Long Shaft Axial Flow Pump (and the rotor could be pull out)

2000----Designed flow rate at 2000 cubic meters per hour

23---Designed head at 23 meters

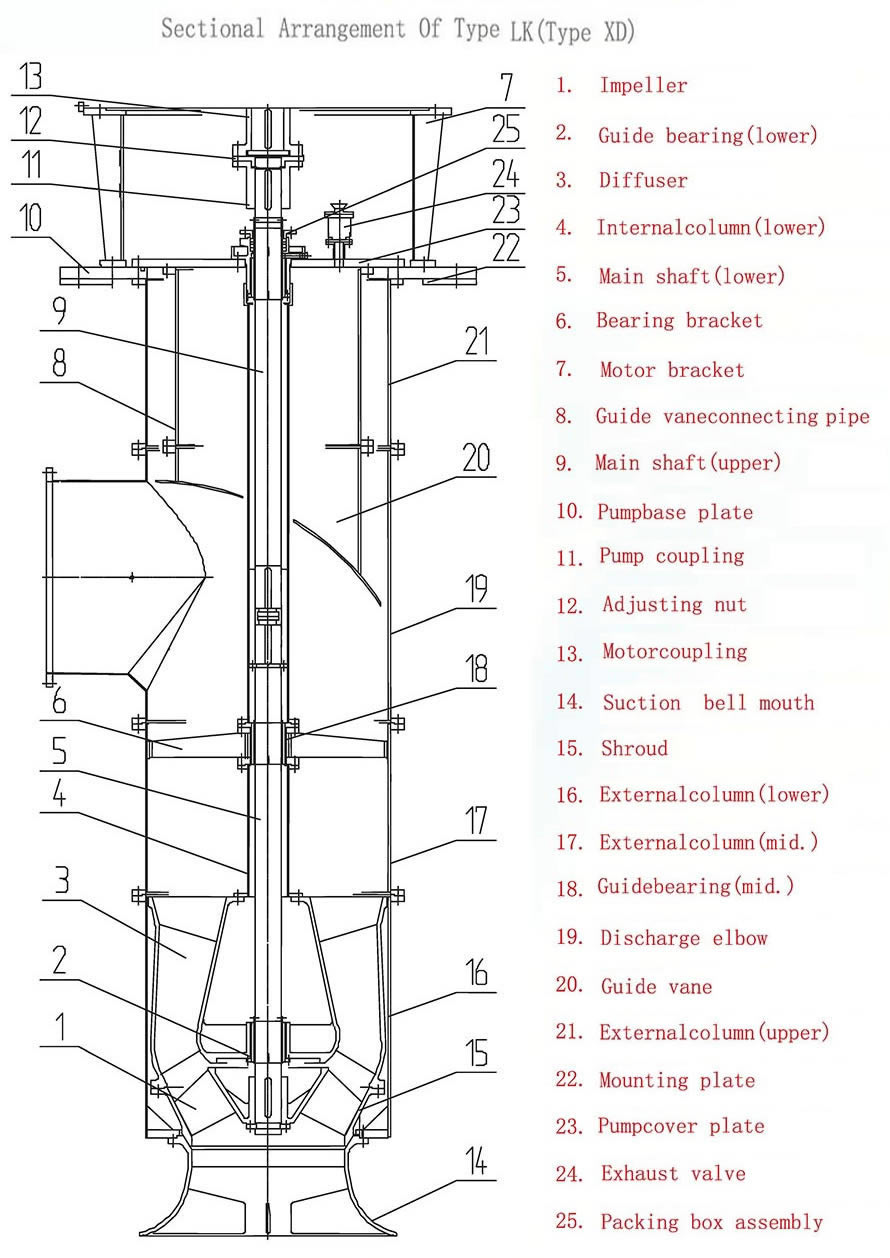

Structure feature:

1. Series HLBK pumps are of vertical single stage axial flow pump

2. The following structure types are available for the pump:the discharge opening above and/or under the mounting foundation(Type Code named S and X respectively);the axial thrust force born by the pump and/or by the motor(Type Code named T and D);lubricating water from outside and/or from the pump itself.

3. The intake sump is of wet pit and/or dry pit types.

Wet pit type:lower part of the pump inundated in the intake sump.

Dry pit type:the water enters into the pump,the suction bellmouth is connected with the inlet pipe of the pump by means of elbow bend pipe of 90.

4. Rubber guide bearings and /or the Thordon guide bearings are available for bearings of the pump.

5. Generally when the nozzle diameter of the pump is under 1000mm , non pull-out type is adopted for the rotor and the discharge opening is above the mounting foundation(Type Code named ST). In this case the axial thrust force and the weight of the rotor are usually born by thrust bearings of the pump itself and flexible connection is adopted between the pump and the motor.The thrust force and the weight of the rotor can also be born by the motor if required,or other structure types such as SD,XT,XD are available .Rotor pull-out type can also be adopted if required by clients.

Generally when the discharge diameter of the pump is above 1000mm, pull-out type is adopted for the rotor and the discharge opening is under the mounting foundation(Type Code named XD).In this case the axial thrust force and the weight of the rotor are usually born by thrust bearings of the motor and rigid connection is adopted between the pump

and the motor. The axial thrust force and the weight of the rotor can also be born by

the pump if required,or other structure types such as XT,SD,ST are available .Rotor non pull-out type can also be adopted if required by clients.

6. When the axial thrust force and the weight of the rotor are born by pump itself,the thrust bearing of the pump is lubricated with dilute oil and is equipped with a temperature detector Pt100 to detect bearing temperature and a pressure type thermometer to detect the temperature of lubricating oil.

7. The antielectrochemical corrosion appliance is adopted for the part of the pump contacting the liquid to ensure the service life of the pump when seawater is pumped.

8. The packing seal is adopted for the axial seal of the pump.

9. The clearance between the impeller and the impeller chamber,i.e.the rotating component and the static component,can be easily adjusted on the pump mounting foundation.

Materials Of Major Parts

|

Major Parts

|

Clear water

|

Seawater

|

Sewage(incl.of abrasiv powder)

|

|

Discharge elbow

Intermediate column (internal & external)

|

Q235-A

|

HT200Ni2Cr

0Cr18Ni9

ZG0Cr18Ni12Mo2

|

Q235-A

|

|

Guide vane,

Suction bellmouth

|

HT200

|

HT200Ni2Cr

ZG0Cr18Ni9

ZG0Cr18Ni12Mo2

|

HT200、QT500-7

ZG1Cr13Ni1

|

|

Impeller

|

ZG1Cr13Ni1 HT200

|

ZG0Cr18Ni9

ZG0Cr18Ni12Mo2

|

QT500-7

ZG1Cr13Ni1

|

|

Shroud,wearing ring

|

HT200

ZG2Cr13

|

ZG0Cr18Ni9

ZG0Cr18Ni12Mo2

|

ZG1Cr13Ni1

QT500-7

|

|

Main shaft

|

45、2Cr13

|

2Cr13、0Cr18Ni9

0Cr18Ni12Mo2

|

45、2Cr13

1Cr18Ni9

|

|

Shaft sleeve

|

45,2Cr13

|

2Cr13、0Cr18Ni9

ZG0Cr18Ni12Mo2

|

2Cr13、1Cr18Ni9

|

|

Guide bearing

|

HT200+abrasive rubber

HT200+Thordon bearing

|

HT200+abrasive rubber

HT200+Thordon bearing

|

HT200+abrasive rubber

HT200+Thordon bearing

|

Remarks:Other materials are available at the request of clients.Cast iron is suitable only for closed type impeller.

|

Performance Data

|

|||||||||||

|

Type

|

Flow rate

|

Head

|

Rotation speed

|

Brake power

|

Matched power

|

Eff.

|

NPSHr

|

Nozzle dia..

|

Weight of

motor

|

||

|

Q

|

H

|

n

|

Pa

|

power

|

Type

|

η

|

|||||

|

m3/h

|

L/s

|

m

|

r/min

|

KW

|

KW

|

%

|

m

|

mm

|

Kg

|

||

|

1000LK-9.4

|

8877

|

2465.8

|

10.8

|

495

|

314

|

355

|

YL5003-12

|

83.5

|

6.7

|

936

|

4250

|

|

10087

|

2802.0

|

9.4

|

295

|

87.7

|

6.9

|

||||||

|

11387

|

3163.2

|

6.9

|

257

|

83.5

|

7.3

|

||||||

|

1000LK-9.9

|

6700

|

1861.1

|

11.4

|

590

|

250

|

280

|

YL4503-10

|

83.0

|

7.0

|

806

|

3270

|

|

7614

|

2114.9

|

9.9

|

235

|

87.3

|

7.2

|

||||||

|

8595

|

2387.5

|

7.2

|

204

|

83.0

|

7.7

|

||||||

|

1000LK-10.5

|

7341

|

2039.2

|

12.1

|

590

|

290

|

315

|

YL4504-10

|

83.1

|

7.4

|

831

|

3330

|

|

8342

|

2317.3

|

10.5

|

273

|

87.4

|

7.7

|

||||||

|

9417

|

2615.9

|

7.7

|

237

|

83.1

|

8.1

|

||||||

|

1000LK-11.9

|

7007

|

1946.5

|

13.4

|

590

|

319

|

355

|

YL4505-10

|

79.9

|

5.5

|

792

|

3450

|

|

8069

|

2241.4

|

11.9

|

308

|

85.2

|

5.8

|

||||||

|

8919

|

2477.4

|

10.2

|

305

|

81.2

|

7.7

|

||||||

|

1000LK-12.7

|

7678

|

2132.8

|

14.2

|

590

|

371

|

400

|

YL5001-10

|

80.0

|

5.9

|

816

|

4000

|

|

8841

|

2455.9

|

12.7

|

358

|

85.3

|

6.1

|

||||||

|

9772

|

2714.4

|

10.9

|

355

|

81.4

|

8.2

|

||||||

|

1000LK-13.5

|

8413

|

2336.8

|

15.1

|

590

|

432

|

450

|

YLS5002-10

|

80.1

|

6.3

|

841

|

4850

|

|

9687

|

2690.9

|

13.5

|

416

|

85.4

|

6.5

|

||||||

|

10707

|

2974.2

|

11.5

|

413

|

81.5

|

8.7

|

||||||

|

1000LK-18.6

|

6681

|

1855.9

|

20.9

|

590

|

451

|

500

|

YL5004-10

|

84.5

|

5.4

|

892

|

4450

|

|

7709

|

2141.4

|

18.6

|

451

|

86.3

|

5.9

|

||||||

|

8634

|

2398.4

|

15.4

|

453

|

79.7

|

6.6

|

||||||

|

1000LK-19.7

|

7320

|

2033.5

|

22.2

|

590

|

524

|

560

|

YL5004-10

|

84.6

|

5.7

|

919

|

4450

|

|

8447

|

2346.3

|

19.7

|

525

|

86.4

|

6.3

|

||||||

|

9460

|

2627.9

|

16.3

|

526

|

79.8

|

7.0

|

||||||

|

1000LK-21

|

8021

|

2228.0

|

23.6

|

590

|

610

|

710

|

YL5601-10

|

84.7

|

6.1

|

947

|

6160

|

|

9255

|

2570.8

|

21.0

|

611

|

86.4

|

6.7

|

||||||

|

10366

|

2879.3

|

17.3

|

612

|

80.0

|

7.4

|

||||||

|

1000LK-41

|

7620

|

2116.8

|

44.3

|

495

|

1108

|

1600

|

YL1600-12

|

82.9

|

6.1

|

1234

|

20300

|

|

9144

|

2540.1

|

41.0

|

1193

|

85.5

|

7.0

|

||||||

|

10770

|

2991.7

|

35.4

|

1252

|

82.9

|

8.5

|

||||||

|

1200LK-10

|

9726

|

2701.7

|

11.5

|

495

|

365

|

400

|

YLT5004-12

|

83.6

|

7.1

|

964

|

4400

|

|

11052

|

3070.1

|

10.0

|

344

|

87.7

|

7.3

|

||||||

|

12477

|

3465.8

|

7.3

|

298

|

83.6

|

7.8

|

||||||

|

1200LK-10.7

|

10657

|

2960.2

|

12.2

|

495

|

424

|

450

|

YLT5005-12

|

83.7

|

7.5

|

994

|

4550

|

|

12110

|

3363.9

|

10.7

|

400

|

87.8

|

7.8

|

||||||

|

13671

|

3797.4

|

7.8

|

347

|

83.7

|

8.3

|

||||||

|

1200LK-11.3

|

11676

|

3243.4

|

13.0

|

495

|

494

|

560

|

YLT5602-12

|

83.8

|

8.0

|

1024

|

6360

|

|

13269

|

3685.7

|

11.3

|

465

|

87.9

|

8.3

|

||||||

|

14979

|

4160.8

|

8.3

|

404

|

83.8

|

8.8

|

||||||

|

1200LK-12.9

|

11146

|

3096.0

|

14.4

|

495

|

542

|

630

|

YLT5603-12

|

80.7

|

6.0

|

977

|

6570

|

|

12834

|

3565.1

|

12.9

|

524

|

85.8

|

6.2

|

||||||

|

14185

|

3940.4

|

11.0

|

518

|

82.0

|

8.3

|

||||||

|

1200LK-13.7

|

12212

|

3392.3

|

15.3

|

495

|

630

|

710

|

YLT6302-12

|

80.8

|

6.3

|

1006

|

10050

|

|

14063

|

3906.3

|

13.7

|

609

|

85.9

|

6.6

|

||||||

|

15543

|

4317.4

|

11.7

|

603

|

82.1

|

8.8

|

||||||

|

1200LK-14.3

|

9218

|

2560.4

|

16.1

|

590

|

502

|

560

|

YLT5004-10

|

80.2

|

6.6

|

867

|

4450

|

|

10614

|

2948.4

|

14.3

|

484

|

85.5

|

6.9

|

||||||

|

11731

|

3258.7

|

12.3

|

480

|

81.6

|

9.2

|

||||||

|

1200LK-17.7

|

8852

|

2458.8

|

20.0

|

495

|

567

|

630

|

YLT5603-12

|

85.0

|

5.1

|

1036

|

6570

|

|

10214

|

2837.1

|

17.7

|

568

|

86.7

|

5.7

|

||||||

|

11439

|

3177.6

|

14.7

|

568

|

80.3

|

6.3

|

||||||

|

1200LK-18.8

|

9699

|

2694.1

|

21.2

|

495

|

659

|

710

|

YLT6301-12

|

85.0

|

5.5

|

1067

|

9600

|

|

11191

|

3108.6

|

18.8

|

661

|

86.8

|

6.0

|

||||||

|

12534

|

3481.6

|

15.6

|

661

|

80.4

|

6.7

|

||||||

|

1200LK-20

|

10627

|

2951.9

|

22.6

|

495

|

767

|

900

|

YLT6303-12

|

85.1

|

5.8

|

1100

|

10450

|

|

12262

|

3406.0

|

20.0

|

769

|

86.9

|

6.4

|

||||||

|

13733

|

3814.8

|

16.6

|

768

|

80.6

|

7.1

|

||||||

|

1200LK-21.3

|

11644

|

3234.3

|

24.0

|

495

|

892

|

1000

|

YLT6304-12

|

85.2

|

6.2

|

1133

|

10820

|

|

13435

|

3731.9

|

21.3

|

895

|

86.9

|

6.8

|

||||||

|

15047

|

4179.8

|

17.6

|

893

|

80.7

|

7.5

|

||||||

|

1200LK-22.3

|

8788

|

2441.2

|

25.1

|

590

|

709

|

800

|

YL800-10

|

84.8

|

6.4

|

976

|

6360

|

|

10140

|

2816.8

|

22.3

|

711

|

86.5

|

7.1

|

||||||

|

11357

|

3154.8

|

18.4

|

711

|

80.1

|

7.9

|

||||||

|

1200LK-27.1

|

8507

|

2363.0

|

29.2

|

495

|

808

|

1120

|

YLT6305-12

|

83.7

|

6.4

|

1034

|

11500

|

|

11342

|

3150.6

|

27.1

|

985

|

84.8

|

7.2

|

||||||

|

13469

|

3741.4

|

22.0

|

964

|

83.7

|

8.9

|

||||||

|

1200LK-30

|

9922

|

2756.0

|

32.4

|

495

|

1043

|

1400

|

YL1400-12

|

83.9

|

7.1

|

1087

|

18000

|

|

13229

|

3674.7

|

30.0

|

1271

|

85.0

|

8.0

|

||||||

|

15709

|

4363.7

|

24.4

|

1244

|

83.9

|

9.8

|

||||||

|

1200LK-49.6

|

10143

|

2817.4

|

53.6

|

495

|

1778

|

2240

|

YL2200-12

|

83.2

|

7.4

|

1355

|

17500

|

|

12171

|

3380.9

|

49.6

|

1916

|

85.7

|

8.4

|

||||||

|

14335

|

3982.0

|

42.8

|

2008

|

83.2

|

10.2

|

||||||

|

1200LK-58.7

|

9120

|

2533.3

|

63.4

|

590

|

1899

|

2240

|

YL2500-10

|

82.9

|

8.8

|

1234

|

13500

|

|

10944

|

3039.9

|

58.7

|

2045

|

85.5

|

10.0

|

||||||

|

12889

|

3580.3

|

50.7

|

2146

|

82.9

|

12.1

|

||||||

|

1400LK-10

|

13187

|

3663.1

|

11.5

|

425

|

492

|

560

|

YL560-14

|

84.1

|

7.1

|

1120

|

9000

|

|

14985

|

4162.6

|

10.0

|

464

|

88.1

|

7.3

|

||||||

|

16917

|

4699.1

|

7.3

|

402

|

84.1

|

7.8

|

||||||

|

1400LK-10.6

|

14449

|

4013.6

|

12.2

|

425

|

572

|

630

|

YL630-14

|

84.2

|

7.5

|

1154

|

11800

|

|

16419

|

4560.9

|

10.6

|

540

|

88.2

|

7.8

|

||||||

|

18535

|

5148.7

|

7.8

|

468

|

84.2

|

8.3

|

||||||

|

1400LK-11.3

|

15831

|

4397.6

|

13.0

|

425

|

665

|

710

|

YL710-14

|

84.3

|

8.0

|

1189

|

16000

|

|

17990

|

4997.3

|

11.3

|

628

|

88.2

|

8.3

|

||||||

|

20309

|

5641.3

|

8.3

|

544

|

84.3

|

8.8

|

||||||

|

1400LK-13.7

|

16558

|

4599.4

|

15.3

|

425

|

848

|

1000

|

YL1000-14

|

81.4

|

6.3

|

1168

|

17000

|

|

19066

|

5296.2

|

13.7

|

822

|

86.4

|

6.6

|

||||||

|

21073

|

5853.7

|

11.7

|

812

|

82.7

|

8.8

|

||||||

|

1400LK-14.5

|

18142

|

5039.5

|

16.3

|

425

|

986

|

1250

|

YL1250-14

|

81.5

|

6.7

|

1204

|

17500

|

|

20891

|

5803.0

|

14.5

|

956

|

86.4

|

7.0

|

||||||

|

23090

|

6413.8

|

12.4

|

944

|

82.8

|

9.4

|

||||||

|

1400LK-18.8

|

13150

|

3652.8

|

21.2

|

425

|

889

|

1000

|

YL1000-14

|

85.5

|

5.4

|

1239

|

17000

|

|

15173

|

4214.7

|

18.8

|

892

|

87.2

|

6.0

|

||||||

|

16994

|

4720.5

|

15.6

|

889

|

81.0

|

6.7

|

||||||

|

1400LK-20

|

14408

|

4002.3

|

22.6

|

425

|

1034

|

1250

|

YL1250-14

|

85.6

|

5.8

|

1277

|

17500

|

|

16625

|

4618.0

|

20.0

|

1038

|

87.2

|

6.4

|

||||||

|

18620

|

5172.2

|

16.5

|

1034

|

81.1

|

7.1

|

||||||

|

1400LK-21.3

|

15787

|

4385.2

|

24.0

|

425

|

1203

|

1400

|

YL1600-14

|

85.7

|

6.2

|

1316

|

19000

|

|

18216

|

5059.9

|

21.3

|

1207

|

87.3

|

6.8

|

||||||

|

20401

|

5667.1

|

17.6

|

1202

|

81.3

|

7.5

|

||||||

|

1400LK-33.2

|

11572

|

3214.5

|

35.9

|

495

|

1345

|

1800

|

YL1800-12

|

84.0

|

7.9

|

1143

|

|

|

15430

|

4286.0

|

33.2

|

1640

|

85.1

|

8.8

|

||||||

|

18323

|

5089.6

|

27.0

|

1604

|

84.0

|

10.9

|

||||||

|

1400LK-60

|

13500

|

3750.0

|

64.8

|

495

|

2852

|

3550

|

YL3600-12

|

83.5

|

9

|

1488

|

|

|

16200

|

4500.0

|

60.0

|

3076

|

86.0

|

10.2

|

||||||

|

19080

|

5300.0

|

51.8

|

3222

|

83.5

|

12.4

|

||||||

|

1600LK-12

|

17346

|

4818.4

|

13.8

|

425

|

774

|

900

|

YL900-14

|

84.4

|

8.5

|

1225

|

|

|

19711

|

5475.4

|

12.0

|

731

|

88.3

|

8.8

|

||||||

|

22252

|

6181.1

|

8.8

|

633

|

84.4

|

9.3

|

||||||

|

1600LK-12.8

|

19006

|

5279.4

|

14.7

|

425

|

900

|

1000

|

YL1000-14

|

84.5

|

9.1

|

1262

|

|

|

21598

|

5999.3

|

12.8

|

850

|

88.4

|

9.4

|

||||||

|

24381

|

6772.6

|

9.4

|

736

|

84.5

|

9.9

|

||||||

|

1600LK-14.5

|

13381

|

3716.9

|

16.3

|

495

|

733

|

800

|

YL800-12

|

81.0

|

6.7

|

1037

|

|

|

15408

|

4280.0

|

14.5

|

709

|

86.0

|

7.0

|

||||||

|

17030

|

4730.5

|

12.4

|

701

|

82.2

|

9.4

|

||||||

|

1600LK-15.4

|

19878

|

5521.6

|

17.3

|

425

|

1147

|

1250

|

YL1250-14

|

81.6

|

7.2

|

1240

|

|

|

22890

|

6358.3

|

15.4

|

1112

|

86.5

|

7.4

|

||||||

|

25299

|

7027.5

|

13.2

|

1098

|

82.9

|

10.0

|

||||||

|

1600LK-16.4

|

21780

|

6050.0

|

18.4

|

425

|

1334

|

1600

|

YL1600-14

|

81.8

|

7.6

|

1278

|

|

|

25080

|

6966.6

|

16.4

|

1294

|

86.6

|

7.9

|

||||||

|

27720

|

7700.0

|

14.0

|

1277

|

83.0

|

10.6

|

||||||

|

1600LK-22.6

|

17297

|

4804.8

|

25.5

|

425

|

1399

|

1600

|

YL1600-14

|

85.8

|

6.5

|

1355

|

|

|

19958

|

5544.0

|

22.6

|

1405

|

87.4

|

7.2

|

||||||

|

22354

|

6209.3

|

18.7

|

1398

|

81.4

|

8.0

|

||||||

|

1600LK-24

|

18952

|

5264.6

|

27.1

|

425

|

1628

|

1800

|

YL1800-14

|

85.8

|

7.0

|

1397

|

|

|

21868

|

6074.5

|

24.0

|

1634

|

87.5

|

7.7

|

||||||

|

24492

|

6803.4

|

19.9

|

1625

|

81.5

|

8.5

|

||||||

|

1600LK-33.3

|

15765

|

4379.1

|

36.0

|

425

|

1827

|

2500

|

YL2500-14

|

84.5

|

7.9

|

1329

|

|

|

21020

|

5838.8

|

33.3

|

2228

|

85.6

|

8.9

|

||||||

|

24961

|

6933.6

|

27.1

|

2179

|

84.5

|

10.9

|

||||||

|

1800LK-12.2

|

23654

|

6570.5

|

14.0

|

367

|

1061

|

1250

|

YL1250-16

|

84.9

|

8.6

|

1422

|

|

|

26879

|

7466.5

|

12.2

|

1004

|

88.7

|

8.9

|

||||||

|

30344

|

8428.9

|

8.9

|

868

|

84.9

|

9.4

|

||||||

|

1800LK-12.9

|

25917

|

7199.2

|

14.9

|

367

|

1234

|

1600

|

YL1600-16

|

85.0

|

9.2

|

1465

|

|

|

29451

|

8180.9

|

12.9

|

1168

|

88.7

|

9.5

|

||||||

|

33247

|

9235.4

|

9.5

|

1010

|

85.0

|

10.0

|

||||||

|

1800LK-15.6

|

27106

|

7529.6

|

17.5

|

367

|

1571

|

1800

|

YL1800-16

|

82.2

|

7.2

|

1440

|

|

|

31213

|

8670.4

|

15.6

|

1527

|

86.9

|

7.5

|

||||||

|

34499

|

9583.1

|

13.4

|

1505

|

83.4

|

10.1

|

||||||

|

1800LK-21.5

|

21528

|

5979.9

|

24.2

|

367

|

1650

|

1800

|

YL1800-16

|

86.1

|

6.2

|

1528

|

|

|

24840

|

6899.9

|

21.5

|

1658

|

87.7

|

6.9

|

||||||

|

27820

|

7727.9

|

17.8

|

1646

|

81.8

|

7.6

|

||||||

|

1800LK-22.8

|

23587

|

6552.1

|

25.8

|

367

|

1920

|

2240

|

YL2500-16

|

86.2

|

6.6

|

1574

|

|

|

27216

|

7560.1

|

22.8

|

1929

|

87.8

|

7.3

|

||||||

|

30482

|

8467.3

|

18.9

|

1914

|

81.9

|

8.1

|

||||||

|

1800LK-25.5

|

20766

|

5768.3

|

28.8

|

425

|

1894

|

2240

|

YL2500-14

|

85.9

|

7.4

|

1439

|

|

|

23961

|

6655.7

|

25.5

|

1902

|

87.6

|

8.2

|

||||||

|

26836

|

7454.4

|

21.1

|

1890

|

81.6

|

9.0

|

||||||

|

1800LK-33.8

|

21600

|

6000.0

|

36.5

|

367

|

2525

|

3550

|

YL3600-16

|

85.0

|

8

|

1546

|

|

|

28800

|

8000.0

|

33.8

|

3081

|

86.0

|

9

|

||||||

|

34200

|

9500.0

|

27.5

|

3012

|

85.0

|

11.1

|

||||||

|

2000LK-13.7

|

28397

|

7888.1

|

15.8

|

367

|

1436

|

1600

|

YL1600-16

|

85.1

|

9.7

|

1510

|

|

|

32269

|

8963.7

|

13.7

|

1359

|

88.8

|

10.1

|

||||||

|

36428

|

10119.0

|

10.1

|

1174

|

85.1

|

10.6

|

||||||

|

2000LK-14.6

|

31114

|

8642.8

|

16.8

|

367

|

1670

|

1800

|

YL1800-16

|

85.2

|

10.3

|

1555

|

|

|

35357

|

9821.4

|

14.6

|

1581

|

88.9

|

10.7

|

||||||

|

39914

|

11087.2

|

10.7

|

1366

|

85.2

|

11.3

|

||||||

|

2000LK-16.6

|

29700

|

8250.0

|

18.6

|

367

|

1827

|

2000

|

YL2000-16

|

82.3

|

7.7

|

1484

|

|

|

34200

|

9500.0

|

16.6

|

1776

|

87.0

|

8.0

|

||||||

|

37800

|

10500.0

|

14.2

|

1750

|

83.5

|

10.7

|

||||||

|

2000LK-17.6

|

32542

|

9039.4

|

19.8

|

367

|

2125

|

2240

|

YL2500-16

|

82.4

|

8.2

|

1529

|

|

|

37472

|

10409.0

|

17.6

|

2067

|

87.1

|

8.5

|

||||||

|

41417

|

11504.7

|

15.1

|

2035

|

83.6

|

11.4

|

||||||

|

2000LK-24.3

|

25844

|

7179.0

|

27.4

|

367

|

2234

|

2500

|

YL2500-16

|

86.3

|

7.0

|

1622

|

|

|

29820

|

8283.5

|

24.3

|

2244

|

87.9

|

7.8

|

||||||

|

33399

|

9277.5

|

20.1

|

2226

|

82.0

|

8.6

|

||||||

|

2000LK-25.8

|

28317

|

7865.9

|

29.1

|

367

|

2599

|

3150

|

YL3150-16

|

86.4

|

7.5

|

1671

|

|

|

32674

|

9076.0

|

25.8

|

2611

|

87.9

|

8.2

|

||||||

|

36595

|

10165.2

|

21.3

|

2589

|

82.2

|

9.1

|

||||||

|

2000LK-27.4

|

31027

|

8618.5

|

30.9

|

367

|

3023

|

3150

|

YL3150-16

|

86.4

|

7.9

|

1721

|

|

|

35800

|

9944.5

|

27.4

|

3038

|

88.0

|

8.8

|

||||||

|

40096

|

11137.8

|

22.7

|

3010

|

82.3

|

9.7

|

||||||

|

2200LK-14.2

|

36801

|

10222.5

|

16.3

|

330

|

1911

|

2240

|

YL2500-18

|

85.4

|

10.0

|

1701

|

|

|

41819

|

11616.5

|

14.2

|

1811

|

89.1

|

10.4

|

||||||

|

47209

|

13113.7

|

10.4

|

1563

|

85.4

|

11.0

|

||||||

|

2200LK-15.1

|

40322

|

11200.6

|

17.3

|

330

|

2223

|

2500

|

YL2500-18

|

85.5

|

10.7

|

1753

|

|

|

45821

|

12728.0

|

15.1

|

2108

|

89.1

|

11.0

|

||||||

|

51726

|

14368.5

|

11.0

|

1819

|

85.5

|

11.7

|

||||||

|

2200LK-18.8

|

35655

|

9904.3

|

21.0

|

367

|

2471

|

2800

|

YL3150-16

|

82.5

|

8.7

|

1575

|

25000

|

|

41058

|

11404.9

|

18.8

|

2405

|

87.2

|

9.0

|

||||||

|

45380

|

12605.5

|

16.0

|

2367

|

83.7

|

12.1

|

||||||

|

2200LK-22.2

|

35579

|

9883.0

|

25.0

|

292

|

2790

|

3150

|

YL3150-20

|

86.8

|

6.4

|

1940

|

32000

|

|

41052

|

11403.5

|

22.2

|

2805

|

88.3

|

7.1

|

||||||

|

45979

|

12771.9

|

18.3

|

2774

|

82.7

|

7.8

|

||||||

|

2200LK-23.5

|

38983

|

10828.6

|

26.6

|

292

|

3246

|

3550

|

YL3600-20

|

86.8

|

6.8

|

1999

|

35000

|

|

44980

|

12494.6

|

23.5

|

3263

|

88.4

|

7.5

|

||||||

|

50378

|

13993.9

|

19.5

|

3226

|

82.8

|

8.3

|

||||||

|

2200LK-28.3

|

40209

|

11169.1

|

31.9

|

330

|

4027

|

4500

|

YL4500-18

|

86.8

|

8.2

|

1940

|

37000

|

|

46395

|

12887.5

|

28.3

|

4048

|

88.3

|

9.0

|

||||||

|

51962

|

14434.0

|

23.4

|

4004

|

82.7

|

10.0

|

||||||

|

2400LK-16

|

44180

|

12272.3

|

18.4

|

330

|

2586

|

2800

|

YL2800-18

|

85.6

|

11.3

|

1806

|

25000

|

|

50205

|

13945.8

|

16.0

|

2453

|

89.2

|

11.7

|

||||||

|

56676

|

15743.3

|

11.7

|

2116

|

85.6

|

12.4

|

||||||

|

2400LK-25

|

42713

|

11864.7

|

28.2

|

292

|

3776

|

4000

|

YL4000-20

|

86.9

|

7.2

|

2060

|

37000

|

|

49284

|

13690.1

|

25.0

|

3797

|

88.4

|

8.0

|

||||||

|

55198

|

15332.9

|

20.7

|

3752

|

82.9

|

8.8

|

||||||

|

2600LK-15

|

51422

|

14284.0

|

17.3

|

292

|

2821

|

3150

|

YL3150-20

|

85.9

|

10.7

|

1975

|

32000

|

|

58435

|

16231.8

|

15.0

|

2677

|

89.4

|

11.0

|

||||||

|

65966

|

18323.9

|

11.0

|

2308

|

85.9

|

11.7

|

||||||

|

2600LK-16

|

56343

|

15650.7

|

18.4

|

292

|

3282

|

3550

|

YL3550-20

|

86.0

|

11.3

|

2035

|

35000

|

|

64026

|

17784.9

|

16.0

|

3116

|

89.5

|

11.7

|

||||||

|

72278

|

20077.2

|

11.7

|

2685

|

86.0

|

12.4

|

||||||

|

2600LK-26.6

|

46800

|

13000.0

|

30.0

|

292

|

4393

|

4800

|

YL4800-20

|

87.0

|

7.7

|

2122

|

40000

|

|

54000

|

15000.0

|

26.6

|

4418

|

88.5

|

8.5

|

||||||

|

60480

|

16800.0

|

22.0

|

4364

|

83.0

|

9.4

|

||||||

Related Products: